The Need for ERP Solution in Manufacturing

By Aveek Pal Chaudhuri

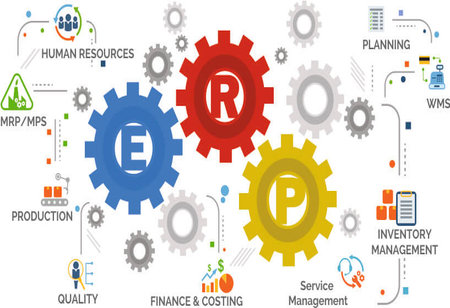

Being a competitive and dynamic industry, the manufacturing industry is authoritative in general and needs for integrated business solutions to increase efficiency, decrease costs and enhance sales and gains. For companies residing in the manufacturing quadrant, the major requirements include the informed and strategic decision making capability. For this reason, an enterprise resource planning structure is the key needed to unchain the shackles of these requirements. ERP technology assembles all business aspects like resources, operations, monitoring, reporting, sales, accounting and finance in one platform. It empowers businesses to operate via an unstoppable paradigm due to a single database maintenance structure.

Being a competitive and dynamic industry, the manufacturing industry is authoritative in general and needs for integrated business solutions to increase efficiency, decrease costs and enhance sales and gains. For companies residing in the manufacturing quadrant, the major requirements include the informed and strategic decision making capability. For this reason, an enterprise resource planning structure is the key needed to unchain the shackles of these requirements. ERP technology assembles all business aspects like resources, operations, monitoring, reporting, sales, accounting and finance in one platform. It empowers businesses to operate via an unstoppable paradigm due to a single database maintenance structure.

In India, the ERP market is seeing massive growth in recent times. A large number of manufacturing firms, automotive, steel, oil, textile and pharmaceutical companies are adopting ERP solutions for bettering the performance and exponentially raising the production curve. Solutions in finance and accounting, sales and distribution, materials management/purchase, manufacturing, etc. are the segments where ERP modules are highly implemented. Also in the segments like plant maintenance, HR, transportation, and service have adopted ERP solutions on a large scale.

Here are the benefits for opting ERP solutions in manufacturing:

- Automation and Streamline Business Processes – A complete range of ERP solution update business processes and includes automation for manufacturing firms. Due to this, the data is available in a focal location in a transparent manner in all functionalities starting from development, designing, inventory, procurement, production, finance, sales, delivery, and others. Also, individuals can monitor the production status in real-time by not taking help from others. Like a designing team can look for the progress of production and inform the buyers and finance and accounts departments if there is any additional requirement of raw materials. This increases the efficiency of the process and enhances productivity with improved customer commitments. Automation processes have reduced the dependence on manual ones, increasing the production speed, reducing the faults and augmenting the profit margin.

- Faster Response to Market Conditions – With real-time data analysis, ERP systems are helping businesses in the estimation, planning, adjustment, and response according to market requirement alterations. The automated reports at constant intervals are helping the decision-makers to equate the production varieties with the varied market demands, thereby helping them on gripping in buyers buying trends. Viewpoints are helping manufacturing inspectors to eliminate errors and take control of upcoming opportunities.

- Decision Making in Strategic Manner – The overall ERP solution is improving the decision making capability of a firm through insights and transparent progress of every department and business segments. Firms are able to take spontaneous, informed, sound, to the point and rapid decisions for ERP solutions. By granting entree to key performance metrics like overall sales or sales margin to manufacturing firms, ERP solutions have made them stick to the business goals with necessary decisions taking prowess.

- Cost Reduction – Perfectly performing ERP software has helped manufacturing organizations to cost reduction in certain areas where the manual process is not needed and thereby saving time. Consuming processes are altered by automation, streamlined process in line with real-time business information. In addition, workers have become more productive. ERP solution has decreased the labor cost by eliminating hidden fault charges. Its ability to trace inventory correctly and assimilate it competently with manufacturing planning has eradicated over the top inventory and warehousing charges. Firms are making savings in every business deal.

- Amplifying Customer Satisfaction – Through proper manufacturing plans, modulation on inventory, streamlined process planning and participation of distribution channels have enabled manufacturers to expand timely delivery of products which is an important measurement component of performance calculation graph. Furthermore, timely product delivery is of the utmost importance to receive customer satisfaction. This is where ERP solutions in manufacturing firms are providing real-time data for decision-makers and helping them to increase customer satisfaction levels.